Wong suggests that the method continues to be evaluated for filling a monoclonal antibody As well as in exploratory studies for vaccines. He suggests that several plans, starting from early- to late-stage scientific, are employing the method.

The resin features of PP are relatively just like that of glass. It's really a much harder and more rigid materials and sometimes instances can be quite a very little tougher to open up with regards to the application.

Since BFS works by using polymer containers, the respective drug shipping and delivery procedure is usually supplied in a variety of fill volumes and container designs, with small changeover time.

In other producing processes, the container is shaped offline and can be terminally sterilized by steam warmth or EtO ahead of it arrives into connection with the drug. Within a BFS process, combining these techniques eliminates the chance to sterilize the container prior to filling.

Our facilities ended up created to overcome indoor air high-quality problems, and is provided with energy economical lighting and ventilation techniques which might be satisfactory for all vital tasks.

It is often used in the meals and pharmaceutical industries for packaging many items. This technology blow fill seal technology allows automate the packaging course of action, expanding performance, and lessening the necessity for guide labor.

The filling chamber during the BFS system is isolated within an ISO-five ecosystem, as well as effectiveness of BFS allows for production campaigns to generally be fulfilled with reputable excellent in spite of container dimensions or quantity.

“A number of the benefits of BFS aseptic packaging consist of minimal human intervention over the filling line, successful production of unit-dose containers at high volumes, power to swiftly scale manufacturing for surge potential, and a consolidated materials supply chain that assists decrease reliance on exterior sources,” claims Josh Myers, senior director, Source Chain, ApiJect.

These alterations have built a big impact on the packaging industry and There is certainly an ever-increasing require to deliver customized, specific packaging methods, which promise the efficiency of medicines.[4]

Operational Performance: BFS devices are highly trustworthy and need negligible human intervention, resulting in superior effectiveness use.

This innovation ensures the highest standards of sterility and effectiveness that's vital for generating Protected and use of blow fill seal in pharmaceuticals efficient pharmaceuticals. BFS supports the manufacture of a diverse variety of health care answers, like ophthalmic medicines and parenteral vaccines.

Just one-sided installation course of action can help lower entry difficulties and increases installation versatility when determining from what facet in the deck or bulkhead to install the pipe seal.

This important process assures that each shaped container is not simply filled but additionally securely sealed, safeguarding the contents within just.

If your container is a person container like a bottle, deep Discovering automated inspection is probably going to generally be a lot more helpful. For any strip of five or 10 ampoules with a card joined collectively, automated inspection would stay a obstacle.

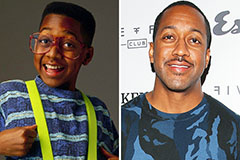

Jaleel White Then & Now!

Jaleel White Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Alisan Porter Then & Now!

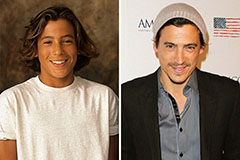

Alisan Porter Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now!